Menu

Dynamometers (or dynos for short) can be found in many different configurations depending on the specific requirement. Engine manufacturers often use engine dynamometers to simulate road loads for testing and EPA requirements. Full-chassis dynos are used to test the entire drivetrain system of the vehicle in a controlled environment. Outside the vehicle industry, mud-motor dynos are used to test the prime mover of the pump used to circulate the fluid for oil well drilling. Top drive dynamometers are used to calculate and test the torque-producing capabilities of the top drive system that is used to rotate the drill pipe. Aerospace fans, handheld tools, gearboxes, oilfield tongs, and clutches are just a sample of some other equipment dynamometers used to test.

At its core, a dynamometer is a tool used to measure the torque and rotational speed of an engine, motor, or other prime movers. This information is collected in real-time, and calculations are performed to display the output power, typically in the form of horsepower or kilowatts. A load must be placed on the rotating device to measure the torque, which is usually done with a brake. There are several methods of braking on a dyno: eddy current, electric motors, hydraulic, and water brakes are some of the more common. In all cases, an excess amount of energy is produced, generally in the form of heat, to create the resistance load needed to measure the torque. Of all the options, the water brake can create the highest loads and absorb the largest amounts of heat.

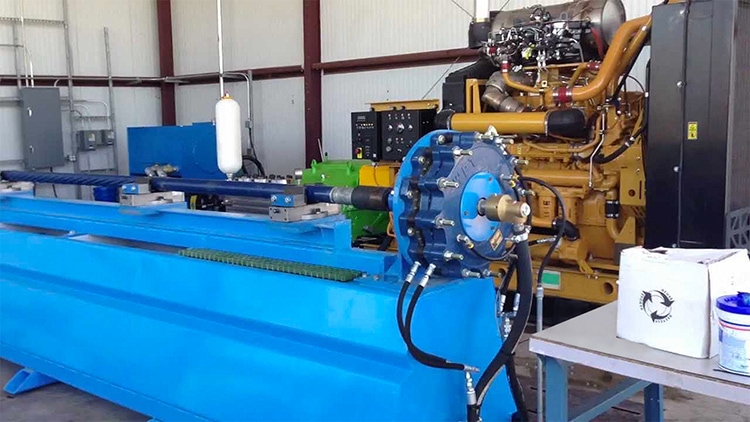

Mud-motor dynamometer with WPT Power Water Cooled Brake on the test stand.

WPT Power has been manufacturing water brakes for over 28 years and with three product lines available, the Steel Water Cooled Brake (SWCB), the Copper Water Cooled Brake (CWCB), and the Water Cooled Brake (WCB), WPT has both the expertise and product selection for all water brake dynamometers. The SWCB and CWCB provide the needed torque and heat dissipation requirements for more minor needs. The WCB can offer an unparalleled torque production and heat dissipation capacity for large dynamometers.

In all the above brake designs, there are four major components: the brake support structure, the water jackets, the drive plates, and the actuator. The brake support structure is secured to the machine or shop floor to resist rotation and support the water jackets. The water jackets are specially designed with chambers to allow water to flow past the friction surfaces to remove the heat generated during the loading. The drive plates are lined with heavy-duty friction material and are connected to a geared hub or shaft to transmit the rotational motion of the prime mover to the brake. The actuator, typically air or hydraulic, is used to provide the force needed to compress the drive plates and water jackets together to produce the resistive rotational force.

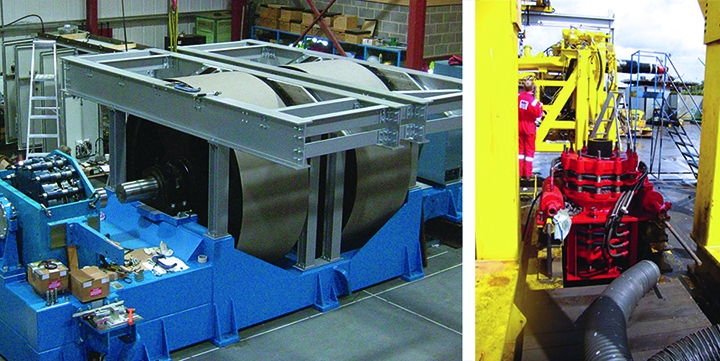

Water Cooled Brake in a dynamometer install for an automotive test stand. Also shown in Top drive application.

The Steel Water Cooled Brake, as the name implies, has water jackets constructed from steel. Since steel is not as good of a conductor, these brakes are typically used in dynamometers with larger torque requirements than heat dissipation. With model sizes ranging from a single-plate 6-inch to a 3-plate 30-inch unit, the SWCB can cover many application requirements.

The Copper Water Cooled Brake is the next step up in heat capacity. Replacing the steel-constructed design of the SWCB in favor of a copper-lined water jacket means the CWCB can dissipate more significant amounts of heat with the same coolant flow. The CWCB is available in single-, double-, and triple-plate units in 14- and 18-inch model sizes.

High-flow, copper-lined water jackets; standard, high, and extra-high coefficient friction linings; multiple actuator options; heavy-duty low drag spring release system; and an available marine corrosion protection package make the WPT Water Cooled Brake a dominant force in the water brake market. The WPT WCB is available in sizes ranging from 14-inches up to 36-inches in single- through quadruple-plate configurations. Plus, the Water Cooled Brake can be mounted in horizontal or vertical orientations with its unique support structure design. For the most demanding dynos, the WCB can be installed in a dual, axial-stacked configuration to provide over 600,000 Nm of torque and 4000 kW of heat dissipation capacity.

So, regarding water-brake dynamometers, WPT Power has both the experience and the products to get you what you need. For more information on the WPT Water Brakes or any of the features listed above, please visit WPTpower.com or call 940.716.1971.