In the Power Grip line of clutches, you may have come across the letters H and SHD at the end of the model numbers. If you are a veteran in the world of industrial clutches, you probably know the H and SHD offer more torque capacity when compared to the standard. What you may not be aware of, is how these two versions of the clutch do that.

What do H and SHD Mean?

Depending on the size, some of the Power Grip clutches may have up to three sub-models. These include the Standard, Heavy Duty (H), and Super Heavy Duty (SHD) models. These can be found at the end of the model names as well as in the parts description.

The History

The original Power Grip clutches were designed for use in the oil field industry. Their primary function was to act as a mechanical disconnect between the drive system and the drum on oil rigs. As time went on, the rigs were designed to lift larger loads. This meant a larger clutch was needed as well.

Retrofitting existing rigs with larger capacity clutches is no easy task. Often the dimensions of a higher capacity clutch are larger. This means fabrication may be needed to make the unit fit. In some cases, there is no room available for a larger clutch.

Thus, a need for a more straight-forward approach was created. The torque had to increase, but the footprint needed to remain the same. This is where the Power Grip clutch H and SHD models come into play.

Increasing the Torque

The standard method of actuation in the Power Grip line of clutches is air. This is accomplished with an airtube that is sandwiched between the holding plate and the pressure plate. When air pressure is applied, the tube expands.

The rated operating pressure is 100 psi (pounds per square inch). This means that for every square inch of airtube surface area in contact with the pressure plate, 100 pounds of force is created in the clutch. This force is what drives the clutch plates together and creates the holding torque.

One method on increasing the force in the clutch is to increase the pressure. However, there are items that must be considered before applying more pressure. For instance, the airtube has a maximum rated pressure. In addition, they are limitations on the air systems maximum capacity.

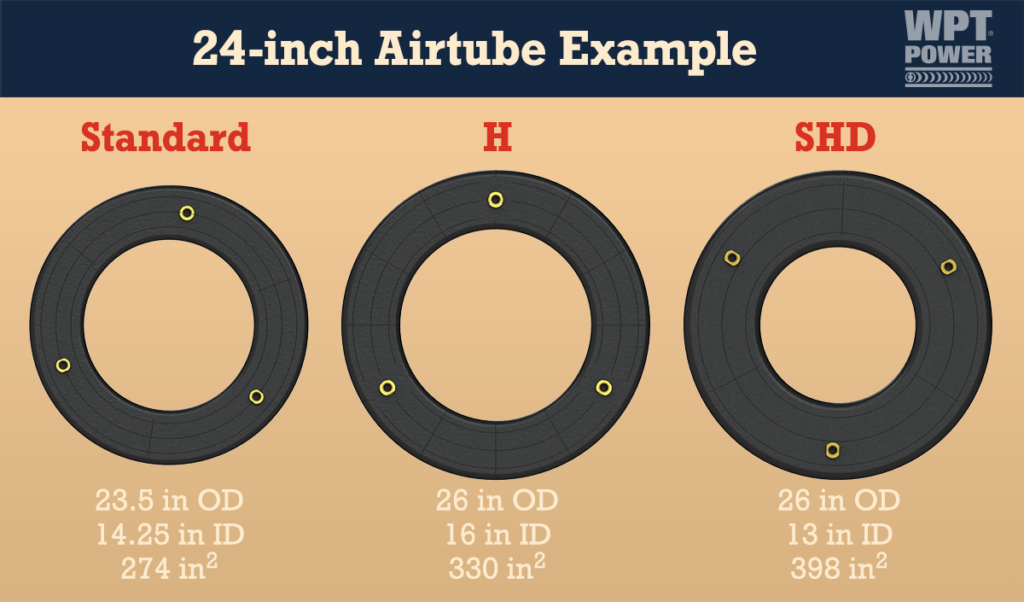

Another method of increasing the engagement force is to increase the area of the actuator. If we apply 100 psi to an airtube with a surface area of 100 square inches, we get 10,000 pounds of force. If we apply that same pressure to an airtube with 150 square inches, we get 15,000 pounds of force. So, by increasing the size of the airtube, we can increase torque in the clutch with minimal impact to the existing actuation setup.

The Clutch Airtubes

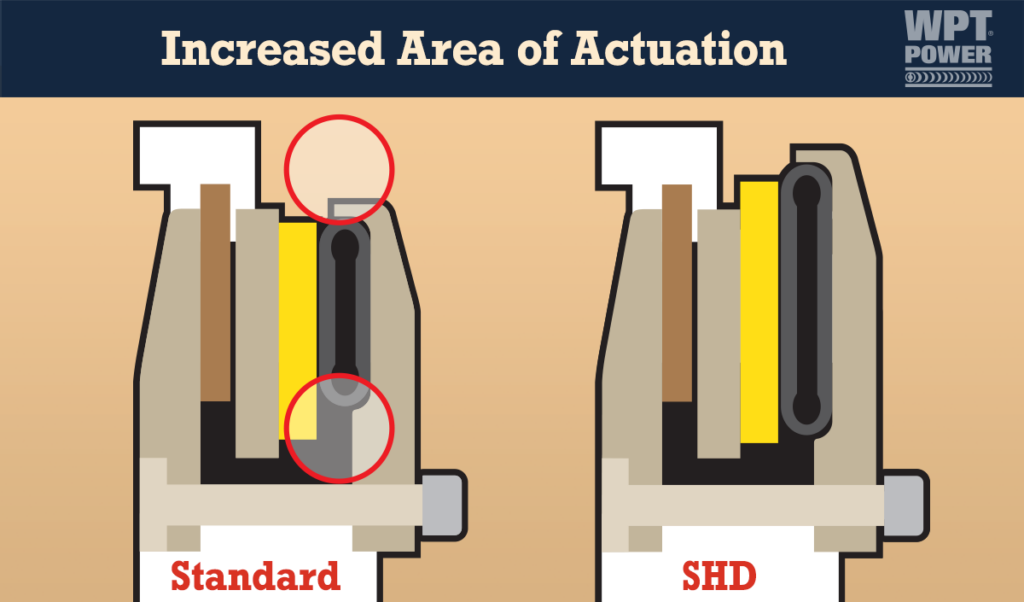

So, how do we increase the airtube size in an existing clutch? If you look at a cross sectional view of a Power Grip, you will notice some empty space. This space is on the inner and outer diameters of the airtube.

The first revision was the model H. It was created by increasing the outer diameter of the airtube, pressure plate, and airtube holding plate (ATHP). The outer diameters of these parts were pushed to the extents of the drive ring diameter. This resulted in a larger actuator surface area that translated into more torque.

For the SHD model, the inner and out diameters of the airtube, pressure plate, and ATHP were increased to create even more surface area. This meant that in the same footprint and same operating pressure as a standard model 114 clutch, a 114SHD would produce over 40 percent more torque.

Clutch Identification

There is an easy way to differentiate between the Standard clutches from the S and SHD models. This is accomplished by looking at the part number. The part number can be found on the brass nameplate affixed to the air tube holding plate.

The standard clutches will start with a W followed by the two-digit clutch size. So, a 24-inch Power Grip part number will start with W24. The H and SHD part numbers are the clutch size, plus one. So, a 24-inch Power Grip H or SHD will start with a W25. An 18-inch H or SHD starts with W19, a 30-inch starts with W31, and so on.

Unfortunately, when it comes to identifying the difference between the H and SHD, there is no easy solution. The only reliable method is to look up the part number and read the part description. Each Power Grip H or SHD clutch description will callout the specific sub-model. This will be on the drawing as well.

In the End

In summary, there are up to three different models of the Power Grip clutch. This includes the Standard, Heavy Duty (H), and Super Heavy Duty (SHD) models. These clutch models are designed to provide more torque in the same amount of space using the same air pressure.

If you are interested in upgrading your current Power Grip clutch to a H or SHD model, please visit the WPT Power website.