Proper maintenance is crucial to getting the performance and life from your WPT industrial clutches. During normal operation of the clutch, the friction discs will wear slowly over time. Below we will show you how to check the operating clearance in your Power Grip PO clutches.

Safety First

If the clutch is still installed on the machine, make sure the equipment is off and proper lockout/tagout procedures for the specific equipment have been put into place before working on the equipment.

Tools You will Need

WPT recommends an analog or digital dial indicator for the most accurate measurement of industrial clutches. If you do not have a dial indicator, then a small straight edge or rule will work in a pinch.

Measuring Clearance – Dial Indicator Method

To measure the clearance in a Power Grip PO clutch with a dial indicator, secure the base of the dial indicator to the top plate. Next, plate the tip of the dial indicator on the insulator plate. You may not be able to see the insulator plate when the clutch is disengaged.

Ensure the dial indicator is set to zero. Engage the clutch with the recommended operating pressure for your equipment. Once the clutch is engaged, record the total indicator movement on the dial. This is the clearance for the clutch.

Measuring Clearance – Straight Edge or Rule Method

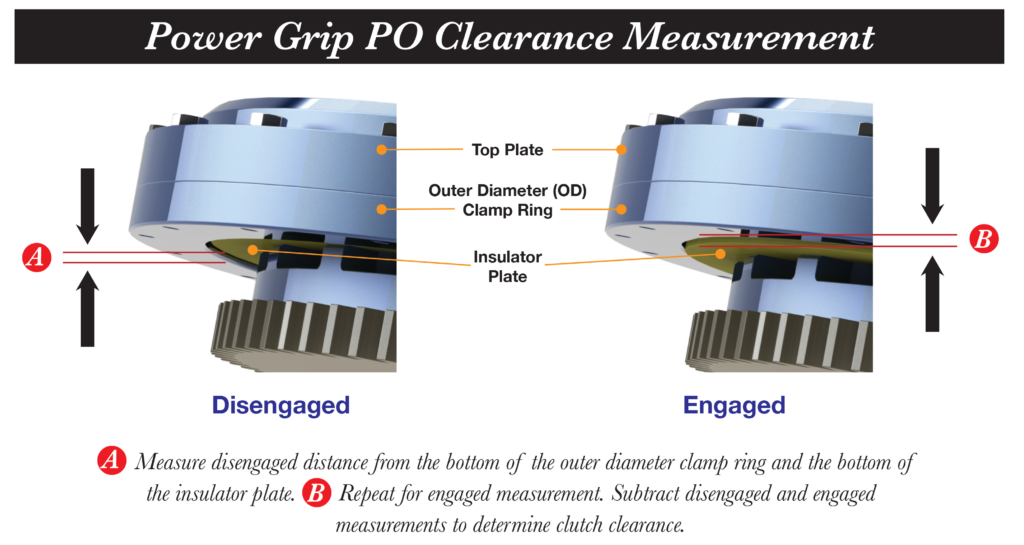

Using a rule or straight edge, measure from the bottom of outer diameter (OD) clamp ring to the bottom of the insulator plate. The insulator plate my be recessed within the OD clamp ring. Record this measurement.

Next, engage the clutch with the recommended operating pressure for your equipment. Once the clutch is engaged, measure the distance from the bottom of the OD clamp ring to the bottom of the insulator plate. Record this measurement.

Calculating the Clearance – Straight Edge or Rule Method

If the insulator plate was recessed in the OD clamp ring when disengaged, you will need to add the two recorded values to calculate the clearance.

Disengaged Distance + Engaged Distance = Clutch Clearance

If the insulator plate was recessed in the OD clamp ring when disengaged, you will need to add the two recorded values to calculate the clearance.

Engaged Distance – Disengaged Distance = Clutch Clearance

Comparing Your Clearance

Compare this value to your WPT manual or clutch assembly drawing. The clearance value should fall within the range specified for your clutch size. If the calculated clearance is beyond the maximum clearance, then it is time to remove shims from the clutch. If the calculated clearance value is below the minimum clearance, then an additional set of shims is required.

Need More?

For more information, please visit the WPT Power website or call us at 940.761.1971.