Many of WPT Power’s recent news releases have focused on improvements to existing clutch, brake, and PTO designs. Similarly, this article focuses on another WPT Power innovation, the Power Performance Low Inertia (PPLI) upgrade for that range of clutch and brakes.

Critical Components

Within the Steel forming and manufacturing sector, a plant’s shear is a critical component in the production cycle directly affecting the finished product. Often steel shears are being ramped up from their original design parameters. Operating at faster cycle rates, higher speeds, and at times being asked to cut thicker gauge material, can result in high temperatures and increased wear rates.

This results in torque loss or inconsistent cuts during the duration of the production run. When shears operate under such conditions, the start of a cycle might be a precise textbook operation but as the unit generates more temperature, the ability to keep itself cool can be affected. The brake may not return to its true home position and the clutch may engage slower which affects the timing of the cut.

What is PPLI?

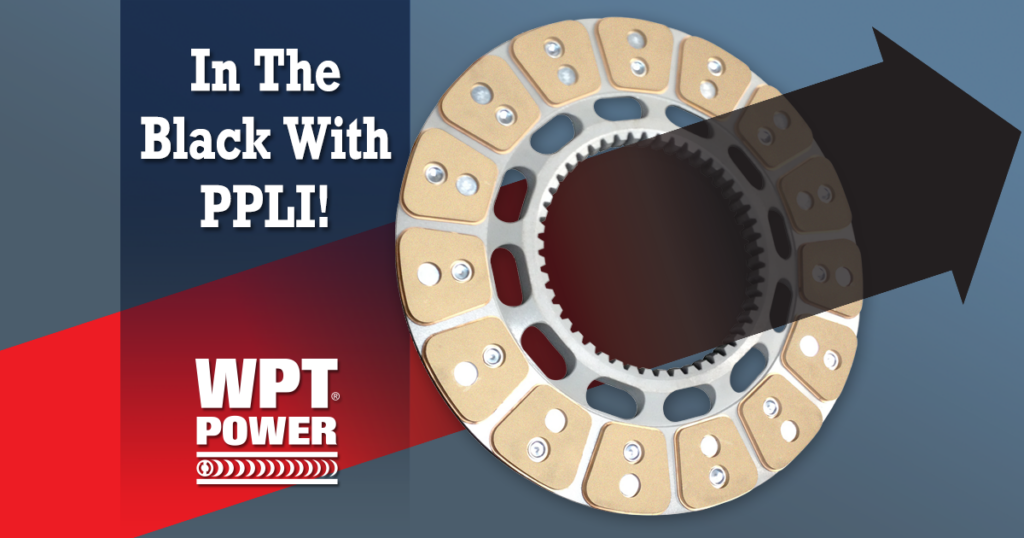

WPT Power has engineered a relatively simple upgrade that offers higher torque capacity, ventilation, and heat absorption, increasing the life of the componentry. This is done by changing two of the components in a standard clutch or brake. The standard molded friction material is removed and replaced with a stress relieved steel drive plate with high-grade sintered iron friction pucks (or buttons). The standard center plates are replaced by high-flow, reduced inertia plates.

PPLI Advantages

The PPLI steel drive plates offer up to 15 percent more torque and a higher temperature threshold. Increased airflow is achieved with the unique arrangement of the friction pucks. The sintered pucks are an excellent heat conductor and offer consistent performance and wear rate.

All speed ratings are maintained against the original molded friction discs. The re-shimming procedure and the use of heavy-duty release springs with the PPLI upgrade take about the same time frame as a normal friction change. This means upgrading your exiting shear for increased torque and more consistent cuts is quick and easy.

The PPLI upgrade is available for 18-, 24-, 30-, and 36-inch models as an upgrade kit or as a completely new assembly. If you would like more information on upgrade options, or to discuss your application in detail, then please contact WPT Power.