At WPT Power, we dedicate ourselves to delivering high-performance products to the many industries and applications they operate in across the globe. This commitment to performance is why WPT Power has become a trusted name in top drive load testing equipment. The most recent example is a test stand in South Africa that uses a WPT Water Cooled Brake (WCB).

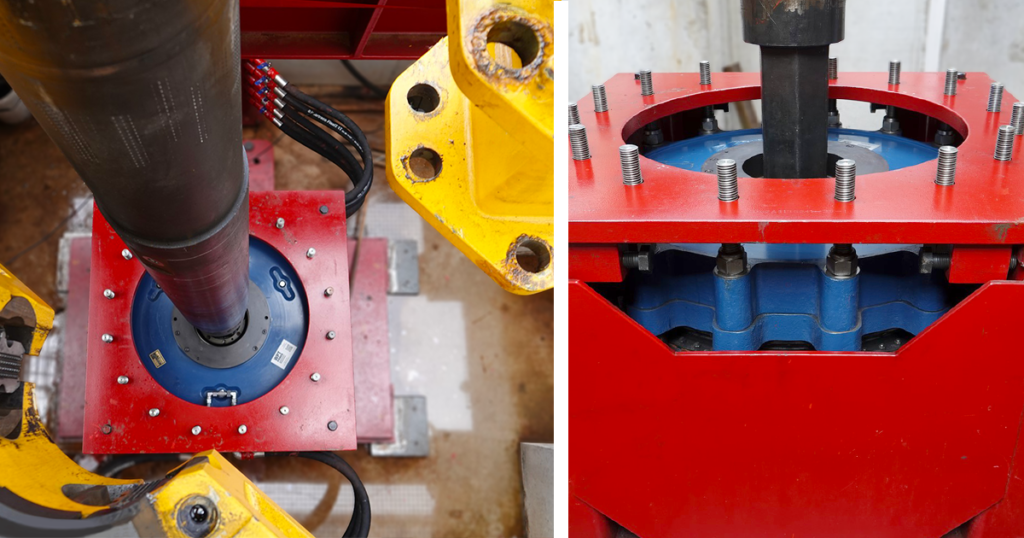

The WPT Power WCB is available in many different configurations. In this latest test stand a 4-plate 36-inch (436) unit was utilized. This test stand is a fixed in ground unit and requires a brake to simulate the operating conditions of various top drive models.

The 436 WCB is a multiple drive plate and water jacket design. The drive plates are lined on each side with friction discs that react against the wear plates. These wear plates are a high-quality copper disc which are fixed and sealed to the high flow water jackets.

This series of plates are forced together with a combination airtube and pressure plate actuator. The airtube method is preferred over other options due to the sensitivity to small changes in pressure. This is the reason the WPT Water Cooled Brake delivers precision torque control. That makes it ideal for load testing and dynamometer applications.

Some of our competitors still use a piston design. These do not offer the same amount of precise torque control as an air tube. Additionally, they are sensitive to small particle contamination and ingress into the seals that damage the piston bore and shorten service life.

The copper plates and water jackets rely on a calculated and constant water flow. Paired with a suitable cooling system we can control the water inlet and outlet temperature differential to ensure our WCB’s do not overheat or lose torque during operation. This level of control makes a great solution for both fixed and mobile Top Drive Test Stands.

While the Top Drive is running on the stand, the WCB replicates the load and resistance it takes to drill into the surface at various depths. The operators are then able to perform various tests on the new or freshly rebuilt Top Drive, such as: continuous loading at preset speeds, static and dynamic overload procedures, and tensile tests. They also collect vibration analysis data, monitor temperatures, and extract lubrication samples before the Top Drive is signed off on and shipped out to the client’s rig.

One of the biggest benefits of choosing WPT Power is how closely we work with our clients to select a brake for your specific needs. Whether it is providing a graph of brake performance at specific air tube pressures or detailed 3D models, WPT gives you all the information needed to make your design process as easy as possible.

If you have any questions regarding tensioning or load simulation applications, please contact WPT Power or give us a call at, 940-761-1971. We have many different options both for smaller drives and for larger equipment.