The WPT Power Water Cooled Brakes (WCBs) get their name from the fact that they use water to transfer energy. This energy is in the form of heat and is caused from the friction material on the drive plates continuously rubbing against the stationary surface of the water jacket. There are several different designs, but the basic principle is that cool water flows into the brake, thermal energy is transferred into the water, and warm water flows out of the brake into an external cooler or reservoir. This allows a water-cooled brake to operate in continuous slip and very high heat applications. Below, we will discuss the top three applications for WPT Water Cooled Brakes: Marine Winches, Drawworks, and Dynamometers.

In marine winch applications—anchor handling, mooring, tug, etc.—the winch needs to maintain constant tension on the payout line. One method of achieving this is to use a dynamic water-cooled brake paired with a feedback loop control system to keep constant tension on the line. With a system in place to monitor tension or torque, the pressure applied to the WCB can be varied to keep proper tension on the line. Because the brakes are water-cooled instead of air-cooled, they can dissipate the massive amount of energy required to provide the proper resistance to the winch. WPT offers a Full Marine Corrosion Protection (FMCP) package that includes a 3-part epoxy coating and stainless hardware that is perfect for the harsh marine environments.

Drawworks are the primary lifting device on a drilling rig for raising pipe out of the well and lowering it into the well. Drawworks usually have two brakes: the main brake and the auxiliary brake. The main brake is typically used as a parking brake after the drum has stopped. The auxiliary brake is usually used when lowering the pipe into the well for further exploration. Because of the large hook loads on modern drawworks, an equally large amount of energy is generated to keep the pipe descending at a constant, controlled rate. Using a WPT Water Cooled Brake is a great way to have a smooth, controlled operation of the blocks while dealing with the excess heat generated. WPT offers Extra High-Coefficient friction linings for increased torque capacity and an Oil Field Version of the WCB that comes standard with a full-release spring compliment.

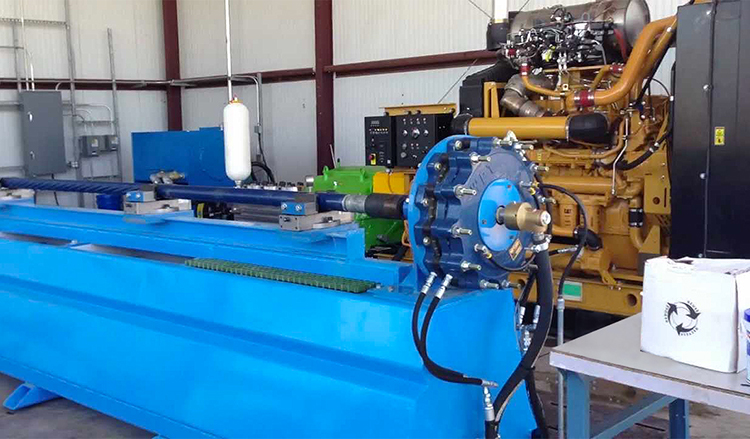

Dynamometers (dynos) are used for various reasons, including determining the instantaneous power of a prime mover, emissions testing, simulated vehicle loading, calibration, tool testing, and many more. In a dyno application, the WCB provides resistance to the rotation. Depending on the input energy, speed, and duration, this can mean a tremendous amount of heat is brought into the system. The WPT Water Cooled Brakes are specifically designed and engineered to transfer this heat and provide reliable torque production for the life of the linings. WPT has a Dyno Quality version of the WCB that features smoother transitions from static to dynamic torque and less drag in the disengaged position.

So, whether you are looking for a sea-worthy brake for your winch, a rugged brake for your rig, or a dependable brake for your dynamometer, the WPT Water Cooled Brake can get the job done. With features like the FMCP package, extra Hi-Co friction linings, full spring compliments, smooth torque transitions, and less drag, the WPT WCB is hard to beat.

For more information on WPT’s marine industry brakes, please visit WPTpower.com or call 940.716.1971.