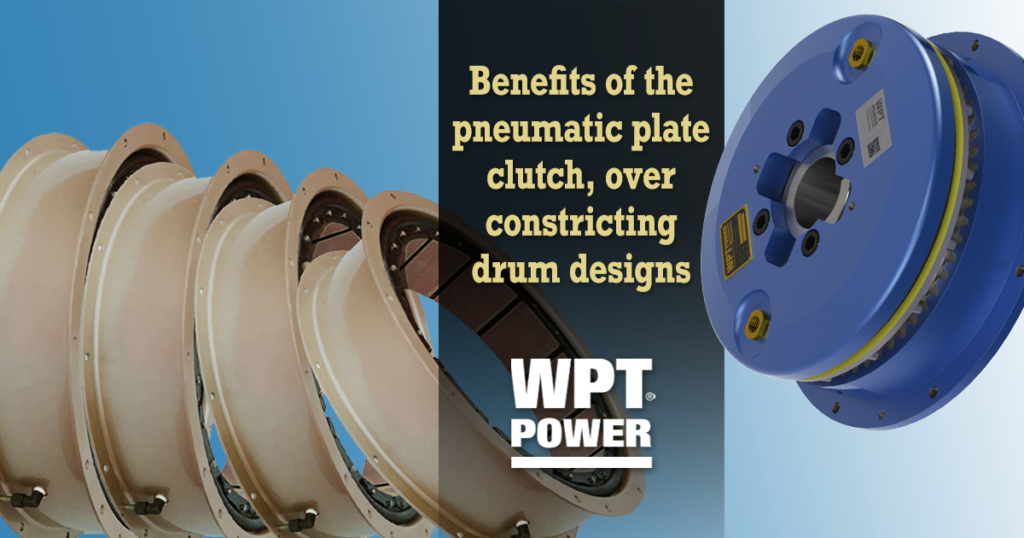

In the industrial clutch and brake game, you don’t have to search very long to find applications that run pneumatic air-cooled plate or disc clutches. Another product style seen is the constricting drum design; these are both found predominately on oilfield equipment, grinding mills, metal forming, paper processing, and marine applications.

There are some key benefits to consider when designing one of these products or conducting a retrofit in the field. This article helps understand the overall benefits of WPT Power’s – Power Grip Clutch, as there are some important factors to consider.

When looking at comparable capacities between the two products, WPT Power can usually downsize the required diameter while either maintaining or increasing the service factor. This is made possible by utilizing the vast friction lining area within the clutch. The WPT Power Grip uses both sides of the friction disc or each disc if it is a multiple-plate model. This all adds to the overall friction material in contact with the mating ductile iron reaction surface.

To display this clearly, here is an example. A drum clutch in a dual wide format in 51” has a lining area of 4,760in², whereas WPT’s Power Grip in a three plate 48” configuration achieves 6,000in². This directly equates to greater torque capacity in a more compact and lighter installation envelope. The benefits you will see from the extra lining area are more flexibility upon startup, calculated slip time, and higher heat dissipation properties. These contribute to increased product performance, reliability, and longer service life.

The flexibility and benefits don’t end here. WPT’s Power Grip Clutch suits both shaft end mounting and shaft-to-shaft installations as seen in grinding mills. The Power Grip can also be inspected and serviced while on the shaft, which is a substantial process and cost-saving benefit, as shaft alignments don’t need to be disrupted, unlike the drum products. Spares can also be ordered for the Power Grip in split format, making the friction discs and air tubes even easier to maintain. Another point to consider is that the Power Grip can be re-shimmed and essentially adjusted in place. It is accomplished by removing the segmented shims to adjust clearance, and this further extends service life and performance.

The Power Grip Clutch range is available in multiple plate configurations. WPT can offer a suitable product for almost every application, even up to a five-plate 60”. No longer do you have to have excessive stock for the different drum sizes and related parts. The advantage of having common spares in your operations that interchange with different unit capacities is significant. WPT Power can factor this into consideration while conducting the drive selection.

The bottom line is that the Power Grip Clutch offers many benefits that deliver upfront and ongoing cost savings. With the support and responsiveness, WPT Power provides, you are sure to get a package to meet your requirements. For further details on the internal anatomy of the Power Grip, please see our assembly video: https://youtu.be/p6k5xLHfMDg or contact info@wptpower.com

Written By: Brett Emson, Sales Manager Asia Pacific & Africa