During the WPT Power Take-off (PTO) operation, the geared friction discs will wear. This is a normal occurrence and happens on all types of clutches and brakes. As the friction disc(s) wear, the torque capacity reduces. To compensate for this reduction in torque, the clutch pack needs to be adjusted. This article will show you how to check engagement torque on a Mechanical PTO so you know when it is time to adjust.

What is Engagement Torque?

In a mechanical PTO, engagement torque is the amount of torque needed to rotate the operating shaft to engage the PTO. Engagement torque is directly related to the amount of clearance, or space between the discs, in the clutch.

More clearance in the clutch pack means less engagement torque. This means your clutch is not producing the maximum power and could slip under high loads. Less clearance in the clutch pack means more engagement torque. Too little clearance and the plates may not separate completely and cause premature wear.

Proper Engagement Torque Range

The engagement torque for your PTO can be found in two places. The most convenient place to find the proper engagement torque is the nameplate. The engagement torque will be listed with a minimum and maximum value. If you have misplaced the nameplate or it is unreadable, the WPT Installation and Maintenance manuals are also a great place to find this. Current manuals are available on the WPT Power website.

Tools Needed

You will need a socket and torque wrench to check the engagement torque range. The two most common torque wrenches are the click- and beam-style. Which one is used will slightly change how to check the engagement torque.

Step 1 – Safety First

The first step is to ensure the equipment is powered down and proper safety measures have been taken.

Step 2 – Disengage PTO

If not done so, use the hand lever to disengage the PTO.

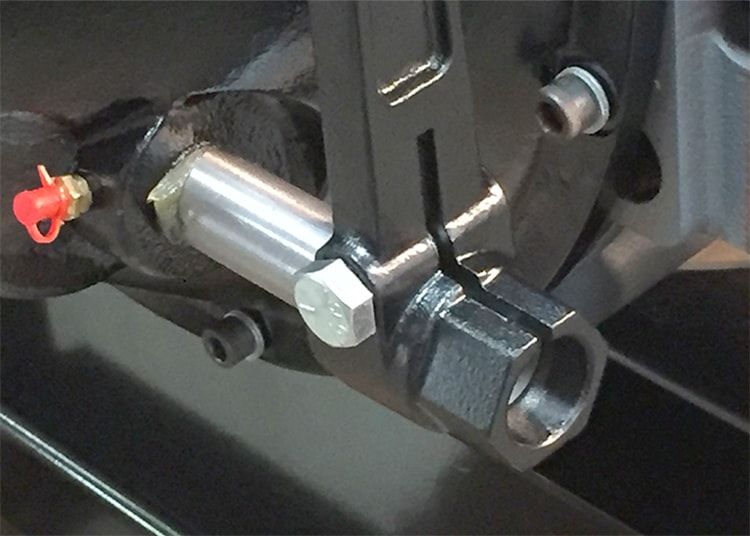

Step 3 – Wrench Placement

Place the torque wrench and socket on the hand lever. The handle lever has a cast hex nut on the bottom near the operating shaft. This should be facing outward from the PTO.

Step 4 – Checking the Engagement Torque

Method 1 – Click Torque Wrench

If you are using a click torque wrench, determining the engagement torque is a two-step process.

First, set the torque wrench to the minimum engagement torque value and engage the PTO using the torque wrench. If the wrench clicks, the engagement torque is above the minimum value. If it does not click, the engagement torque is below the minimum value and adjustment is needed.

Second, set the torque wrench to the maximum engagement torque value and engage the PTO. If the wrench clicks, the engagement torque may be above the maximum value, and adjustment is recommended. The engagement torque is below the maximum value if it does not click.

Method 2 – Beam Torque Wrench

The process of using a beam torque wrench is simpler but requires a keen eye.

While watching the needle and dial, engage the PTO with the torque wrench. The needle position during engagement should be above the minimum and below the maximum engagement torque values. If the needle is above or below, adjustment is needed. If the needle falls between the values, no adjustment is required.

Adjusting the Engagement Torque

If the engagement torque is above or below the proper values, the following setup will be to adjust the PTO. For steps on how to complete this, see the How to Adjust Engagement Torque on a Mechanical PTO article.

How Often to Check

Checking the engagement torque is a crucial maintenance procedure to help get the most from your WPT Power Take-off. This should be checked more frequently on new units or when parts have been replaced. Afterward, it is best to set up a regular preventative maintenance schedule to check and record the engagement torque as needed.

The frequency of checks should be adjusted to suit your specific application. Going too long without checking runs the risk of damaging your PTO. So, it would be better to check more frequently than less.

For More Help

For more help or information on your WPT PTO, please visit our website at www.WPTpower.com or give us a call at 940-761-1971.

Written By: J.D. Bodine, Senior Sales Engineer