The expectation placed on modern tree care equipment today is more demanding than ever before. The machinery is being tasked with running harder and longer all the while maintaining a reliable service life. The key to reliable service life is establishing a proper preventative maintenance schedule for key components of the machine.

One key component commonly found in tree care equipment is the mechanical Power Take-off (PTO). The mechanical PTO is mounted to the engine and provides a mechanical disconnect between the engine and the drum or disc of a grinder or chipper. In this type of arrangement, not only does the PTO control the transfer of power, but it can also act as safeguard. A PTO damaged during an overload can delay a job by hours or days, but an engine damaged during an overload can cause weeks of downtime and tens of thousands of dollars. One of the more common causes of downtime in a PTO is premature bearing failure. This can be caused by several reasons, but improper lubrication and over-tensioning of the belts are two of the leading causes. Below are some steps that can be taken to increase the life of the PTO.

First, develop a regular greasing interval. Refer to the machine or PTO manual for a baseline, but adjustments to the amount and frequency may be necessary based on the use and operating environment of the machine. Most people know that too little grease is not good for a bearing, but too much grease can be just as detrimental. Check the seals around the shaft or vent ports for excessive grease build-up. A little grease is normal, but if there is large amount, less grease may be required to get the maximum life from the bearing.

Next, ensure the belts are set to the machine manufactures recommended tension. The effect of an under-tensioned belt is more noticeable, but an over-tensioned belt can go undetected until it is too late. The best way to determine correct belt tension is to ensure everyone is trained correctly and performs the check the same way each time. Often the belt tension is set to high and this puts excess force on the bearings that lead to premature wear or even failure.

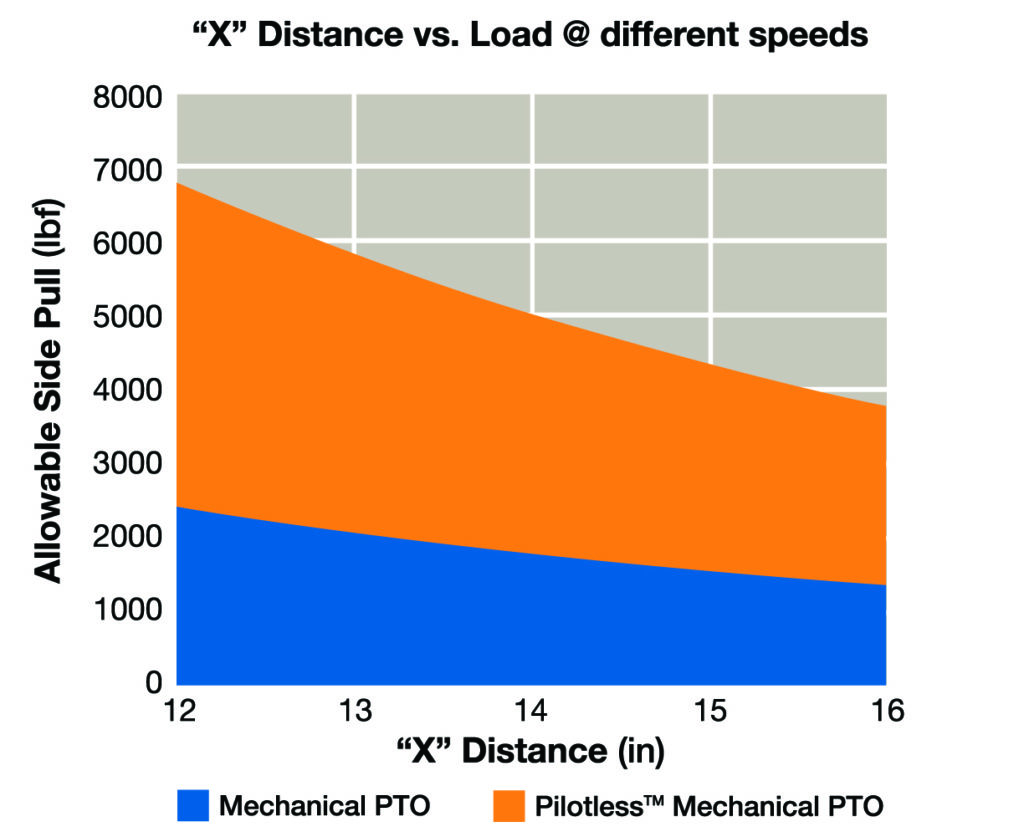

Even with proper maintenance and operation, there are times when the demands from the machine exceed the performance specifications of the PTO. In that event, it may be time to consider an upgrade. WPT Power developed the Pilotless® Mechanical Power Take-off with the tree care industry in mind. The new PTO has a reduced maintenance design and upgraded heavy duty bearings for maximum belt tension (sideload) capacity.

The Pilotless® Mechanical PTO features a robust bearing actuation assembly and the lubrication interval has been extended from 20 to 100 hours. This means there is less time maintaining the equipment and more time on the job. WPT removed the pilot bearing in favor of a pair of high-capacity spherical roller bearings. These upgraded bearings increase the sideload capacity up to 70 percent which allows for maximum uptime of the machine. For new equipment designs, the increased sideload capacity allows for the use of smaller sheaves and pulleys. This translates into big savings for the manufacturer.

For more information on how to get most from your current PTO or for more information on the WPT Pilotless® PTO visit WPTpower.com or call 940.716.1971