Road planers, dredges, and other equipment require power from some type of engine to perform their designed function. Without a power take-off, it would be necessary to add a second engine to provide the power required to run hydraulic pumps and other driveline attached equipment.

Adding an additional engine is simply not practical, which makes power take-off (PTO) a valuable element in providing power to secondary functions. To recognize their value requires a better understanding of these systems, their various types, and their diverse applications.

Understanding Power Take-Offs

Power take-offs allow mobile crushing plants, road milling machines, and other vehicles to perform auxiliary functions without needing an additional engine to power them. A PTO is a device (a mechanism) usually seated on the flywheel housing, which transfers power from the driveline (engine) to a secondary application. In most cases, this power transfer applies to a secondary shaft that drives a hydraulic pump, generator, air compressor, pneumatic blower, or vacuum pump.

Selecting the Right PTO

PTO choice is critical to provide sufficient power to the auxiliary equipment without severely limiting the main function of the prime mover. Selection of a power take-off requires specific information relating to the application and the power needs of the secondary or driven component.

Here is a quick list of considerations for PTO selection:

- Torque and horsepower requirements of the driven component

- Intermittent or continuous operation

- Application usage

- Speed requirements of the driven component

- Mounting face dimensions and options

- Space allocation

- Method of PTO engagement

Having these specifications available makes the proper selection of a PTO a simple task.

PTO Torque and Horsepower Requirements

Speed and rotation requirements of a PTO are among the most critical specifications in the list above, with speed being necessary for calculating torque. The torque and horsepower requirements of the driven component are essential for optimal performance.

In most cases, the owner’s manual of the driven component will provide this information, but the calculation of these requirements, if necessary, is relatively straightforward using two basic formulas.

- HP = GPM x PSI ÷ 1714

HP (horsepower) = GPM (pump flow in gallons/minute) x PSI (pump pressure required pounds/inch) ÷ 1714 (conversion factor to yield HHP or hydraulic horsepower). This formula provides the horsepower requirement for the driven component, used in calculating the torque requirement.

- T = HP × 5252 ÷ RPM

T (torque) = HP x 5252 (the rpm rate where both torque and horsepower intersect) ÷ RPM (RPM rate of the drive shaft of the driven component).

Keep in mind that these calculations only apply to PTOs that drives a hydraulic pump. In cases where power take-off is providing power to a different type of drive component, it will require the manufacturer’s specifications of the driven element.

The Different Types and Industrial Applications of PTO Clutches

Though they perform the same general function—transferring power from the primary drive shaft to a secondary drive shaft for a driven component—there are various PTO types available that serve specific industrial applications. These diversifications are why WPT Power supplies OEM’s units in agricultural, energy, forestry, and road building sectors, among others.

Pilotless Mechanical PTO

The distinguishing characteristic of this type of PTO is the intentional removal of the pilot bearing. Benefits of this design feature come with an increased side load capacity, reduced inventory, increased uptime and engine life, and a quicker and easier installation. Industrial applications of the Pilotless Mechanical PTO include:

- Chippers

- Rock crushers

- Irrigation pumps

- Water blasters

- A wide variety of other heavy-duty Road Building & Construction machines

Mechanical PTO

This type of flywheel PTO applies to either inline or sideload uses. It includes a sealed-for-life pilot bearing, utilizing a lever-actuated manual clutch. The benefit of this type of PTO is a straightforward installation which minimizes downtime and maintenance requirements. This type most commonly applies to:

- Engine packages

- Pump jacks

- Barge pumps

- Wood chippers

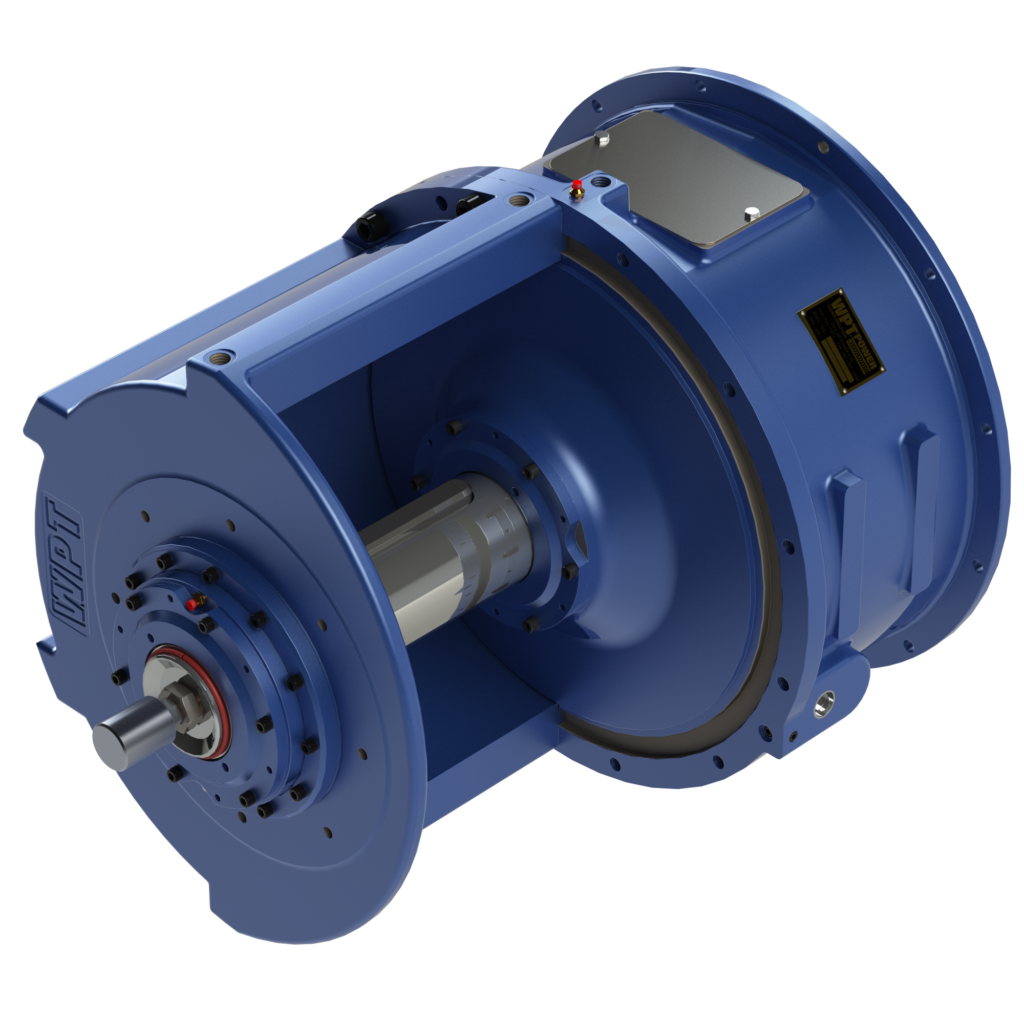

Type 1 PTO

This is a rugged, high-capacity power take off used in a broad range of industrial functions. Characteristic of this type of PTO are the sheaves between heavy-duty spherical roller bearings designed to utilize their full load potential. This bearing arrangement reduces the damage produced by crankshaft loading. Among the most common applications for the Type 1 PTO are:

- Mud pumps

- Dredges

- Rock Crushers

- Mobile chippers

Type 2 PTO

The design of the Type 2 PTO features a heavy-duty side loading capacity using sizeable spherical roller bearings. Actuation of this PTO can be either hydraulic or pneumatic. It is self-adjusting and removes the need for the pilot bearing inside the engine flywheel. Features include reduced maintenance, less chance of premature failures, and improved engine and bearing life since there is no direct loading to the crankshaft. Common applications for Type 2 PTOs include:

- Road building equipment (milling machines, stabilizers)

- Portable Rock Crushers

- Tub grinders

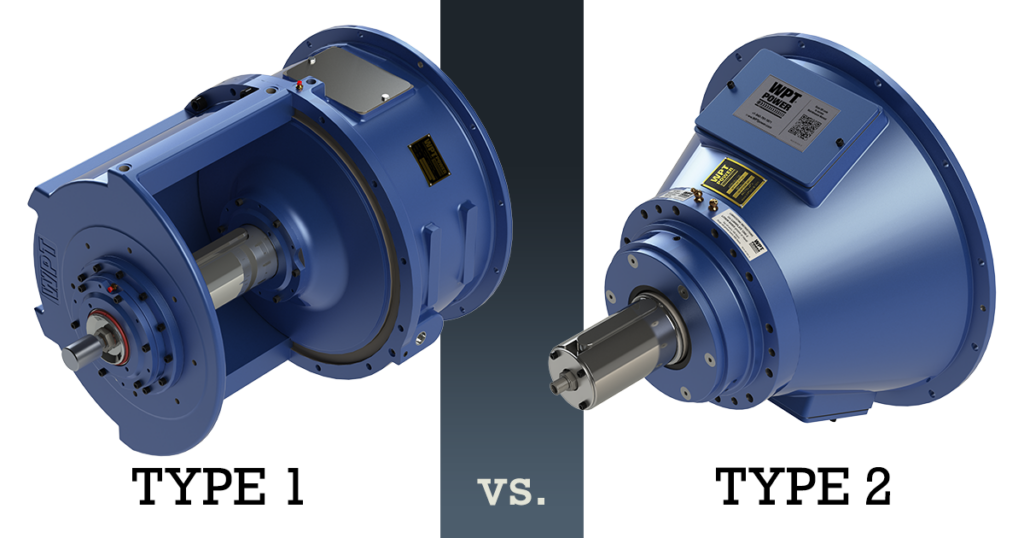

Type 1 vs. Type 2 PTO Clutches

The difference between these two PTO clutch types is their varied functional designs.

- Type 1 PTOs include 2-4 times the side load capacity of a Type 2 PTO, so they best suit heavier, industrial applications with high impact loading.

- Type 2 PTOs allow for high-capacity loading in a smaller footprint and are best for light-to-medium capacity side loading.

Pilotless Over-the-Shaft PTO

This PTO design eliminates the need for the pilot bearing while providing increased side loading or inline potential. Its engineering accommodates the most demanding requirements of high-loading diesel engines. Features include simple installation, reduced downtime, and improved engine service life. This style of PTO is used on inline applications with its hydraulic and air fittings. They are mounted near the bell housing instead of at the rear of the shaft like type 1 and type 2.

GM Style PTO

The GM Style PTO reduces maintenance time and cost by using sealed main bearings and eliminating the need for the pilot bearing. Designed to mount directly to GM® style engines, these operate without the need for any particular PTO or engine adaptations. Notable features include clutch adjustments using an external ball stud and jam nut adjustment points.

Automotive Style PTO

Also known as “flat-faced” style PTOs, they incorporate similar design characteristics, features, and benefits of the GM style PTO. It is a spring-loaded clutch making it easier to engage and disengage than over the center power take-offs. Typical uses include irrigation units, brush chippers, or other gas or diesel engine applications.

Common Operational PTO Clutch Problems and Solutions

PTOs are relatively simple mechanical units with minimal operational problems, but a few common issues are associated with them, and each has a straightforward solution. Here are some of the most frequently encountered issues:

- The Clutch will not disengage. Slipping and overheating are common causes of these issues and are fixable by disassembling, inspecting, and replacing if necessary.

- Clutch will not stay engaged. Improper adjustment is the most common cause, remedied through adjusting engagement torque.

- PTO is hot. A newly installed PTO will run hot for the first 10-20 hours of operation after installation. Several issues contribute to overheating (220º F measured by infrared thermometer at the bearing carrier), including too much or too little grease, excessive sideload, or a new installation. Follow proper lubrication specifications and reduce the sideload to remedy the first two problems.

Get the Right PTO for Your Needs at WPT Power

Getting the appropriate PTO to meet your operational needs is a priority at WPT Power. Manufacturing our PTOs takes place in our ISO 9001:2015 facilities, where all our products are engineered to meet the highest standards of quality demanded by our customers. ABS type approvals and ATEX certifications minimize risks, time, and costs. Type approval certification available: DNV & ABS (Others available on request)

Sales, Customer Service, and Engineering are available without all the phone menu options and department shuffling. When you call for technical questions, application design, or place an order, you talk to a real person. WPT serves many types of markets globally including:

- Steel and Metal Forming

- Marine

- Agriculture

- Forestry

- Dynamometer

- Energy

- Road Building

- Mining/Aggregates

- Paper Converting

Our broad range of products is developed to meet most requirements on standard industrial applications. Custom or modified PTOs are available for original equipment manufacturers (OEM) requiring specialized design and where volume is needed.

Power take-offs play an essential role in allowing for the transfer of power from a primary mover to a secondary or driven component without needing an additional separate engine. Various PTO types serve many applications, from smaller-scale operations to major industrial and construction projects. Choosing the correct PTO for a specific application is critical to the proper performance of the driven component.

Contact us for more information about the range of solutions offered by WPT Power Corporation, for assistance in selecting the right PTO to fit your specific application, or request a quote from one of our experts.